AgriNomix offers innovative horticulture and greenhouse automation products to provide growers with next-level solutions. For over 30 years, we’ve blended cutting-edge, industry-leading technology with decades of knowledge and expertise to help growers boost yields and save resources.

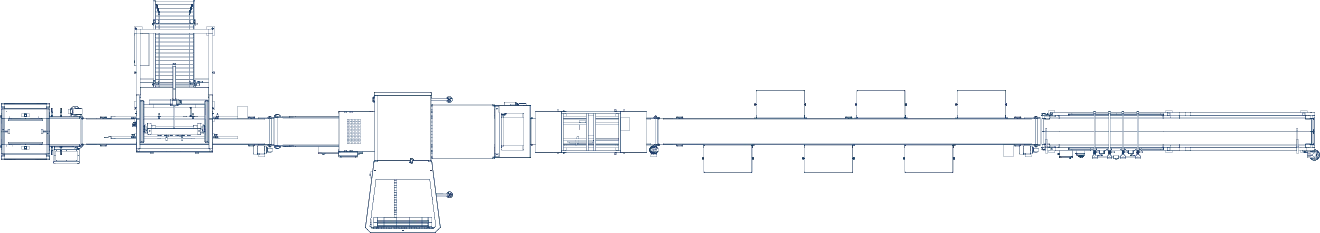

Custom Automation Solutions

Every grower’s process is unique. That’s why AgriNomix designs and builds complete custom automation systems — not just stand-alone machines.

Our engineers partner directly with you to understand your production flow and tailor solutions that streamline every step—from tray filling and seeding to watering, transplanting, and potting.

Explore Our Systems

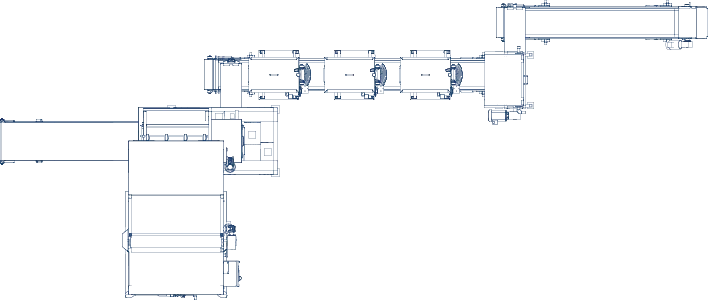

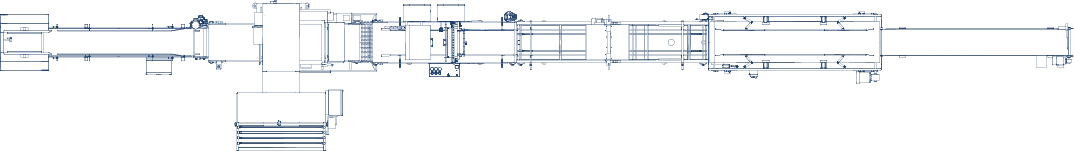

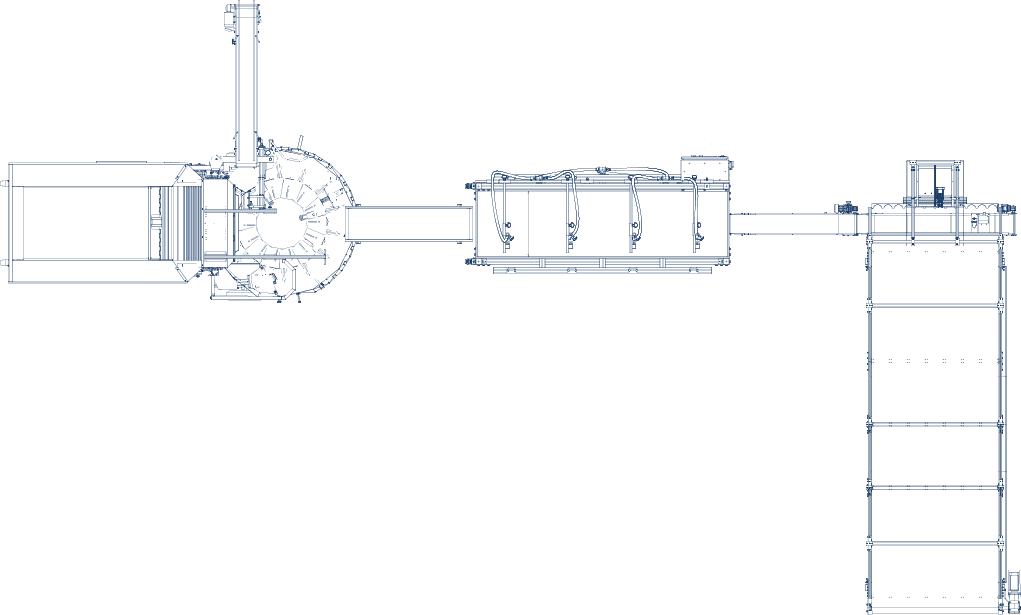

Small Soil System

See System Details

VBT Bale Shaver

Whether it’s peat or pre-mix, the VBT Bale Shaver delivers consistent media texture and flow from the top of the bale to the bottom. The palletized bale is placed inside the machine, the doors are closed, then an elevator feeds the bale into the horizontal scraper that acts as a harrow to evenly extract the peat or pre-mix layer-by-layer. Improved processing maximizes compressed bale yield and moisture content consistency.

Explore Product

HydraFiber Expander Unit

Designed for growers with one to two planting lines. Compact footprint installs easily into existing mix lines. Processes up to 25 cubic yards of blended soil per hour. Returns compressed HydraFiber Ultra bales to their fibrous state and blends with base media. Tungsten carbide-coated shredder rollers ensure robust performance. Powered in-feed conveyor. Available in right- or left-hand versions. Can be fed directly from bale shaver or mix line.

Explore Product

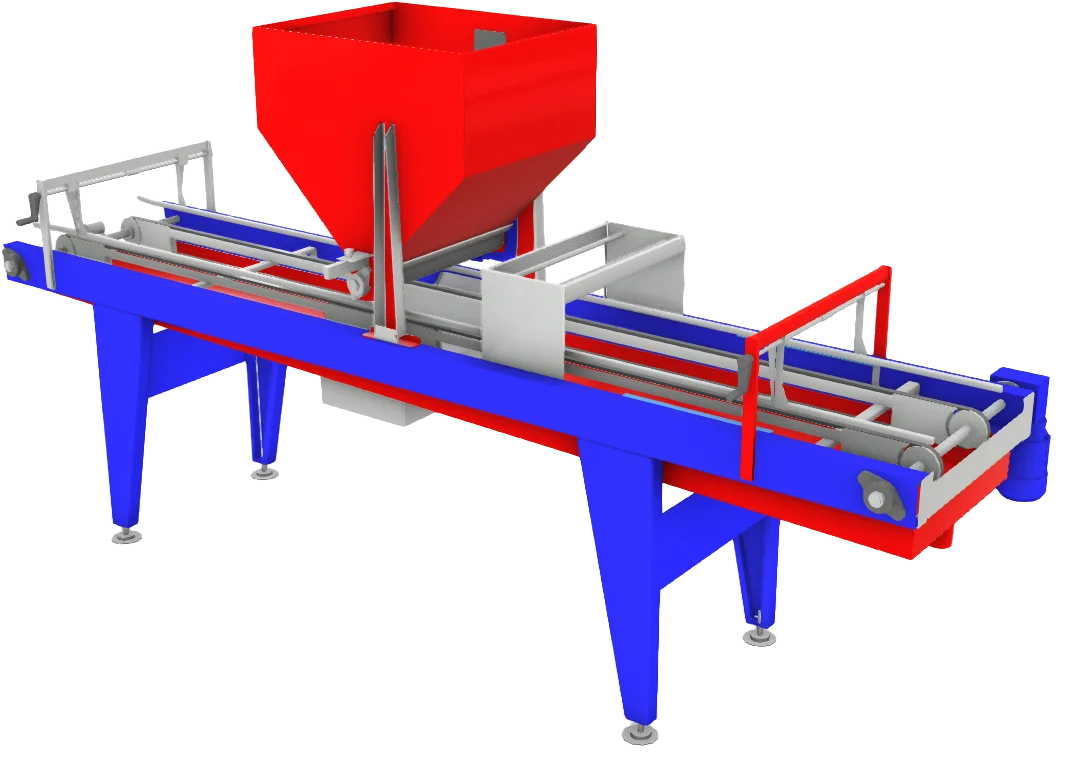

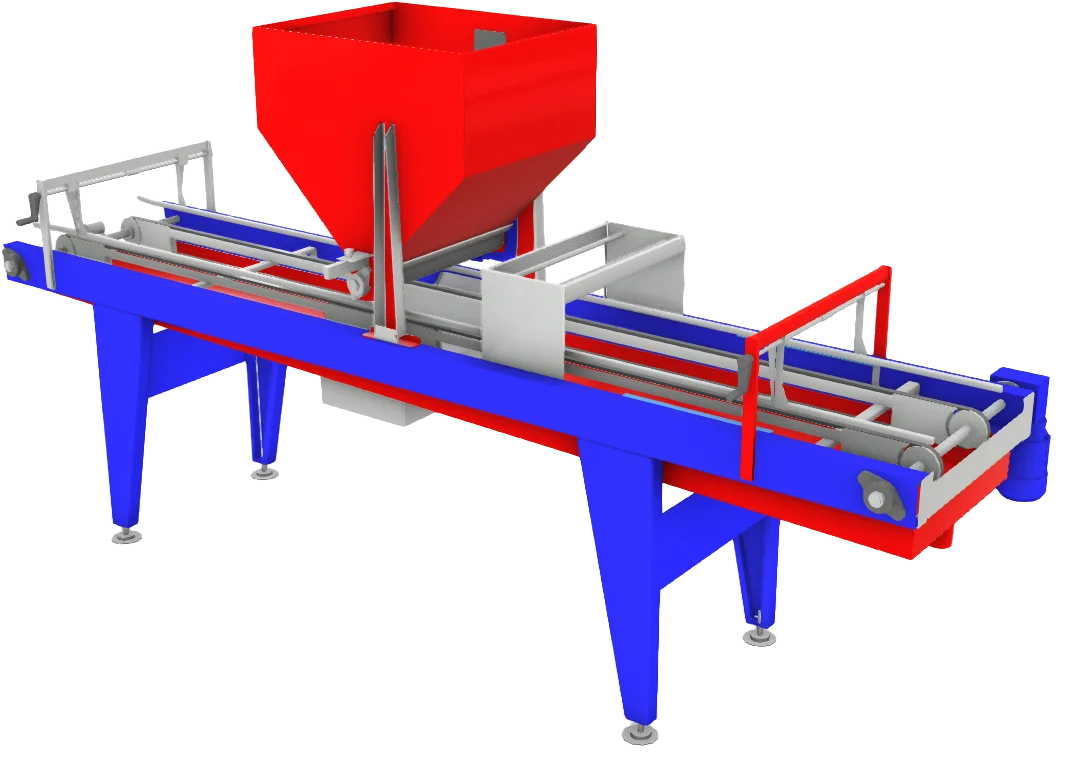

Chemical Hopper

Precisely dispense chemical amendments like lime and wetting agents into your soil blending line. Compact stainless-steel hopper features a variable-speed belt that meters material beneath an adjustable gate, then distributes it via dispersion fan to break apart clumps for even coverage.

Flow sensors and load cells track material dispensed while low-level alarms minimize supervision and prevent material runout. Designed for seamless integration into automated soil delivery systems.

Soil Processor

Increase throughput and ensure consistent growing mixes with our auger-driven soil processors. Blends and conditions peat, coir, bark, and premix substrates into uniform, ready-to-use media. Integrated water bar with solenoid valve automates moisture adjustment, reducing manual labor. Mixer bar delivers even particle distribution for optimal water retention and aeration.

Explore Product

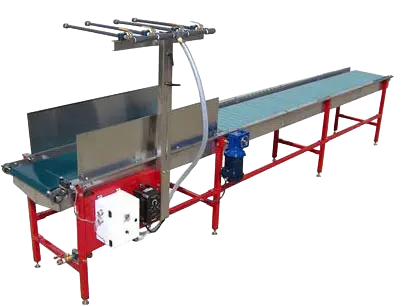

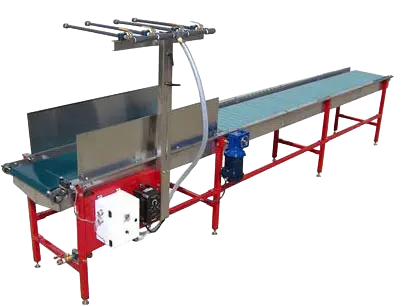

Soil Conveyors

Modular galvanized steel construction in 18" and 24" widths for superior strength. Powder-coated heavy-duty steel legs provide stability and adjustability. Easily modify existing conveyors by adding or removing prefabricated sections. The 18" model (slide rail bed) handles up to 36 yd³/hr; 24" model (roller bed) handles higher volumes with low-profile troughing for tight spaces. Adjustable belt speeds from 200–400'/min. Available in 10' to 70'+ lengths. Custom-built to your facility layout.

Explore Product

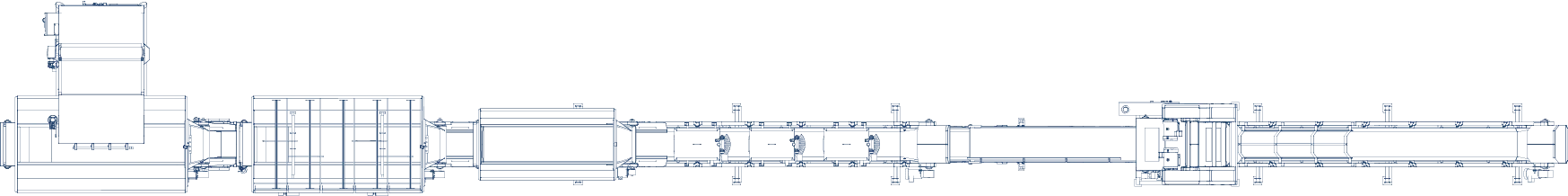

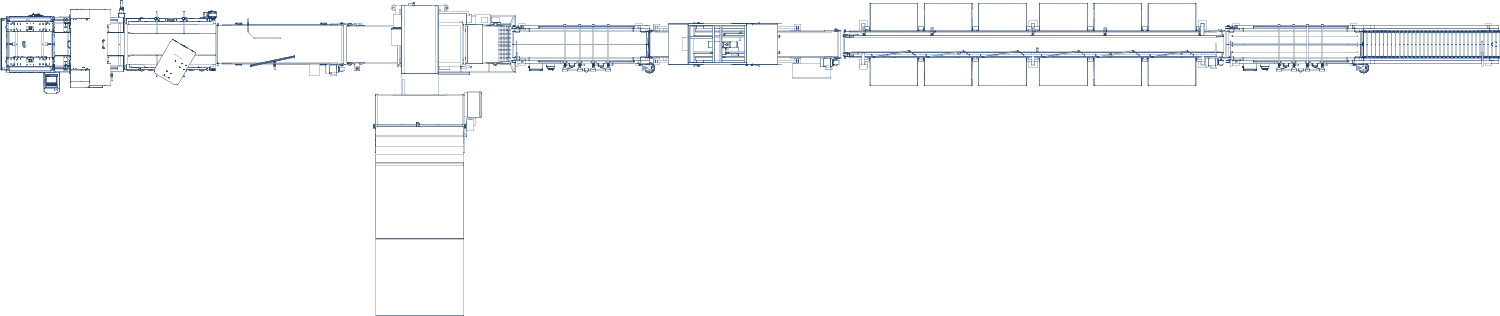

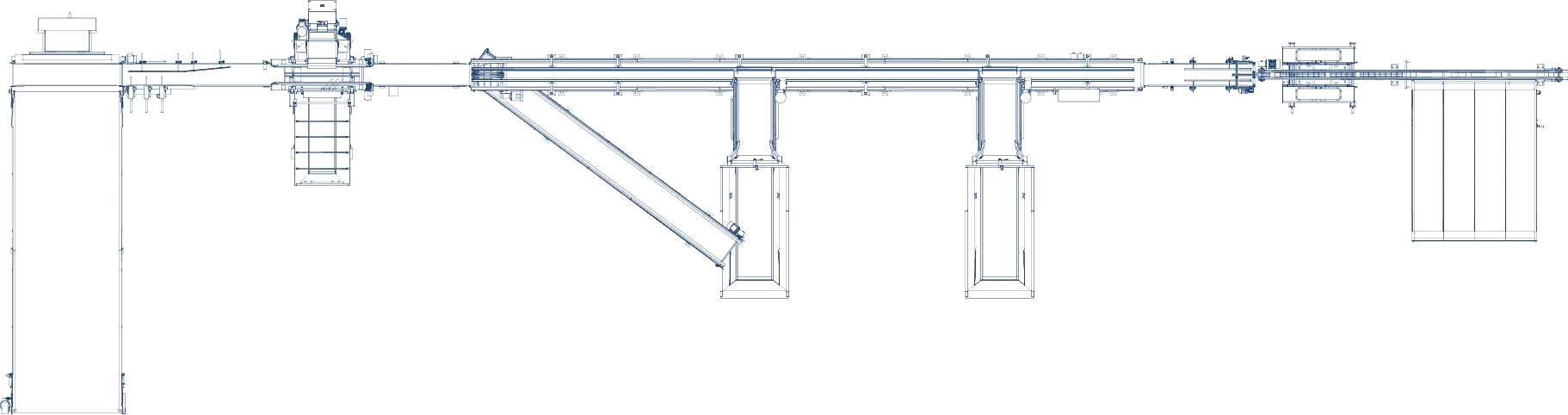

Large Soil System

See System Details

VBT Bale Shaver

Whether it’s peat or pre-mix, the VBT Bale Shaver delivers consistent media texture and flow from the top of the bale to the bottom. The palletized bale is placed inside the machine, the doors are closed, then an elevator feeds the bale into the horizontal scraper that acts as a harrow to evenly extract the peat or pre-mix layer-by-layer. Improved processing maximizes compressed bale yield and moisture content consistency.

Explore Product

Bulk Hoppers

AdeptAg Bulk Hoppers are engineered and built for utilization in soil mix systems or as standalone material supply hoppers. The heavy gauge galvanized steel construction is designed to withstand various nursery and greenhouse-protected environments. With the modular design, these hoppers can be configured in a wide range of capacities dependent on the base model.

Explore Product

Bulk Hoppers

AdeptAg Bulk Hoppers are engineered and built for utilization in soil mix systems or as standalone material supply hoppers. The heavy gauge galvanized steel construction is designed to withstand various nursery and greenhouse-protected environments. With the modular design, these hoppers can be configured in a wide range of capacities dependent on the base model.

Explore Product

Chemical Hopper

Precisely dispense chemical amendments like lime and wetting agents into your soil blending line. Compact stainless-steel hopper features a variable-speed belt that meters material beneath an adjustable gate, then distributes it via dispersion fan to break apart clumps for even coverage.

Flow sensors and load cells track material dispensed while low-level alarms minimize supervision and prevent material runout. Designed for seamless integration into automated soil delivery systems.

Chemical Hopper

Precisely dispense chemical amendments like lime and wetting agents into your soil blending line. Compact stainless-steel hopper features a variable-speed belt that meters material beneath an adjustable gate, then distributes it via dispersion fan to break apart clumps for even coverage.

Flow sensors and load cells track material dispensed while low-level alarms minimize supervision and prevent material runout. Designed for seamless integration into automated soil delivery systems.

HydraFiber Processing Unit

The HydraFiber Processing Unit (HPU) processes and mixes up to 100 cubic yards of blended soil per hour. Returns compressed HydraFiber Ultra bales to their fibrous state and blends with base media using integrated soil recipe controls. Tungsten carbide-coated shredder rollers ensure robust performance. This unit simplifies the blending process, making it ideal for high-volume operations that demand consistent, high-quality soil mixes.

Explore Product

Soil Conveyors

Modular galvanized steel construction in 18" and 24" widths for superior strength. Powder-coated heavy-duty steel legs provide stability and adjustability. Easily modify existing conveyors by adding or removing prefabricated sections. The 18" model (slide rail bed) handles up to 36 yd³/hr; 24" model (roller bed) handles higher volumes with low-profile troughing for tight spaces. Adjustable belt speeds from 200–400'/min. Available in 10' to 70'+ lengths. Custom-built to your facility layout.

Explore Product

Seeding Line

See System Details

Multi-Stack Tray Dispenser

Automatically dispenses shuttle trays, plug trays, and individual packs. Use stand-alone or integrate into any production line. Single-stack model is manually loaded; multi-stack version auto-loads stacks via upper conveyor and returns dispensed trays via lower belt. Adjustable settings accommodate a wide range of tray sizes. Throughput up to 2,100 flats per hour (multi-stack). Reduces labor costs and increases efficiency for operations handling a variety of plants and container sizes.

Explore Product

RN-12 Plug Tray Filler

Unmatched uniformity from specially designed linear agitators ensuring consistent filling end-to-end and side-to-side. Easy and fast adjustment with just 2 handles. Innovative system achieves desired soil compaction levels. Fills up to 800 trays per hour with containers up to 8.5″ tall. Standard features include built-in line integration, extra capacity soil return, variable speed soil supply, and variable speed belt control.

Explore Product

Lambda Drum Seeder

The Lambda can be equipped with 1–3 seeding drums for staggered plug trays, multiple seed types, and/or granulated chemicals. Available stand-alone or as part of a complete line. Electronically controlled drums sow a wide range of seeds in single or multiple quantities with high accuracy. Sows up to 650 trays per hour (one seed per cell). Tool-free drum changeover for fast tray and seed changes. User-friendly control panel with keypad and view screen stores up to 99 seeding programs.

Explore Product

Covering/Watering Unit

The Covering/Watering Unit enhances any seeding line by applying uniform top coating of media and distributing water evenly across trays as they exit the seeder. Activates only when a tray is detected, reducing waste. Vermiculite drum hopper with adjustable settings controls media flow. Two laser-drilled water bars ensure consistent application for optimal germination. Integrates with Urbinati seeder touchscreen controls. Additional water bars available for expanded distribution requirements.

Explore Product

Sub-Irrigator

The Sub-Irrigator provides the advantages of ebb-and-flow irrigation in an in-line setup. It is ideal for use in seeding, propagation, and shipping lines, where uniform watering is needed and overhead watering is either insufficient or not desirable. The final watering before shipping can be critical; the sub-irrigator fully waters the roots without applying moisture to the upper parts of the plant, therefore nearly eliminating the possibility of mold during shipping.

Explore Product

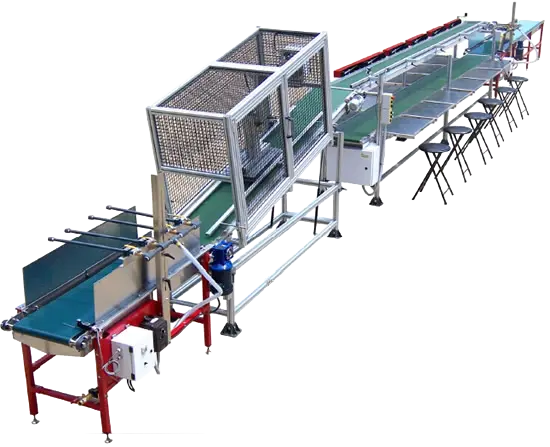

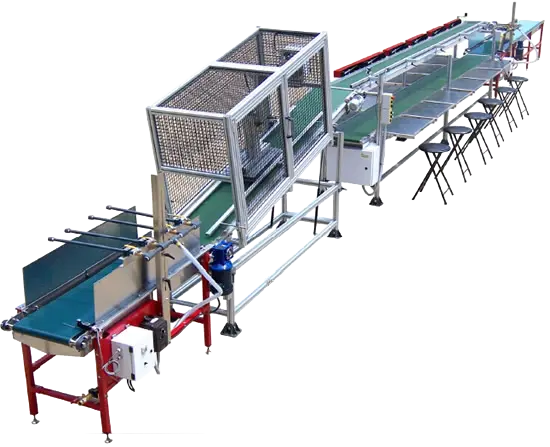

Production Line Conveyors

Production Line Conveyors are proven to significantly reduce material handling and increase productivity. They may be utilized to set the pace of a crew by bringing the work to the workers, verse moving your crew. These conveyors can be integrated into production lines to seamlessly move the product through the various tasks of production from the infeed to the take-off area. AdeptAg has a broad offering of conveyor lengths and widths to fit the various needs for the greenhouse industry.

Explore Product

Cuttings Lines

See System Details

Automatic Advanced Growcoon Dispenser

Streamline your propagation process by automating the precise placement of Growcoons into trays. The Advanced model uses pick and place technology to deliver up to 56,000 Growcoons per hour at 1.2 seconds per row with superior accuracy and reliability.

Handles heights from 0.7–2.8" and top diameters from 0.4–3.9" across a wide range of tray and Growcoon combinations. Integrates into existing tray filling lines with optional tray destacker for continuous operation

RN-12 Plug Tray Filler

Unmatched uniformity from specially designed linear agitators ensuring consistent filling end-to-end and side-to-side. Easy and fast adjustment with just 2 handles. Innovative system achieves desired soil compaction levels. Fills up to 800 trays per hour with containers up to 8.5″ tall. Standard features include built-in line integration, extra capacity soil return, variable speed soil supply, and variable speed belt control.

Explore Product

DB40 Peat Moss Bale Processor

The DB40 processes compressed big-bales up to 2.6m high, restoring original substrate volume without affecting structure. Easy to move with pallet jack or forklift, low maintenance, and compatible with almost all brands of potting machines and fillers. Multiple options available to make production easier and more efficient.

The DB40 Peat Moss Bale Processor is compatible with almost all brands of potting machines and fillers.

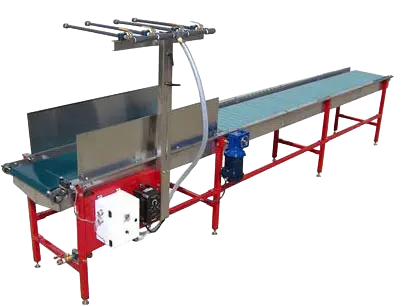

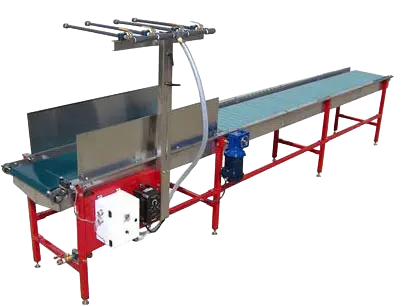

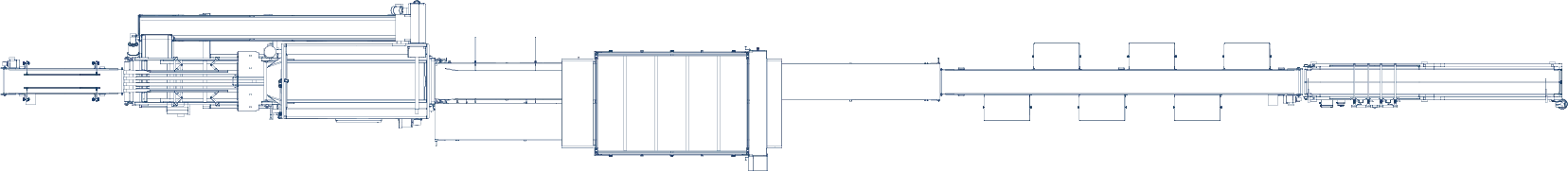

7 Foot Water Tunnel System

The 7 Foot Water Tunnel provides controlled watering for flats, trays, pots, and baskets. Available with 16″ or 22″ powered conveyor belt with variable speed. Standard 4-bar water manifold and drain pan. Wires into production line controls, watering stops and starts with the line to prevent over/under-watering. Keeps plants uniformly moistened without wasting water. Optional extra wide or tall units accommodate hanging baskets with hangers.

Explore Product

High-Speed Dibbler

Dibble holes in pots and flats for uniform placement and planting depth at speeds up to 2,800 containers/hour. High-speed pneumatics and precision controls deliver consistent results. Magnetic dibble pins attach quickly to metallic mounting plate for ultimate flexibility and fast changeovers. Set hole locations by positioning pins directly in the pot or tray, then lower the plate with the built-in hand crank. Versatile design meets the demands of high-speed lines with frequent product changes.

Explore Product

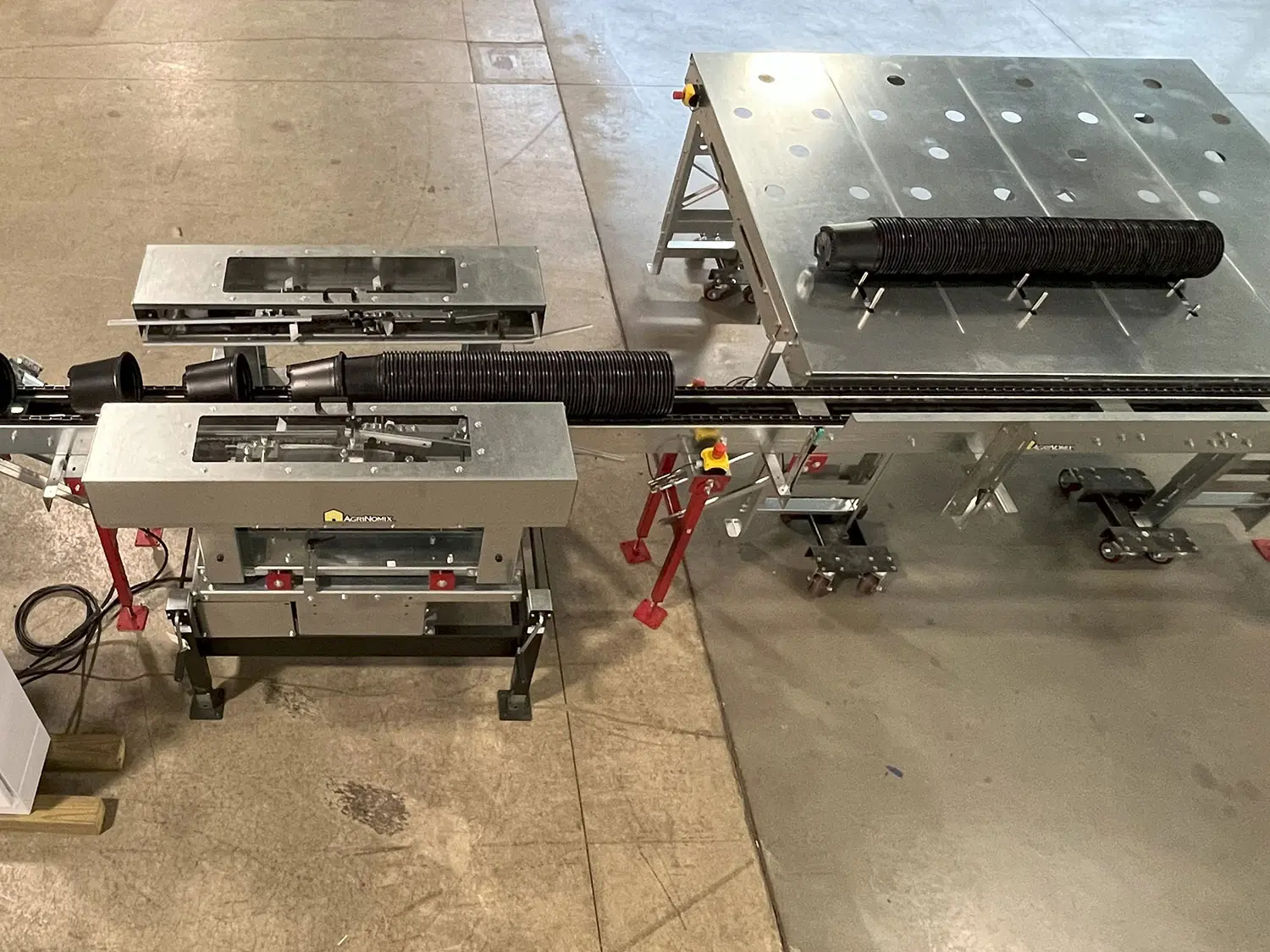

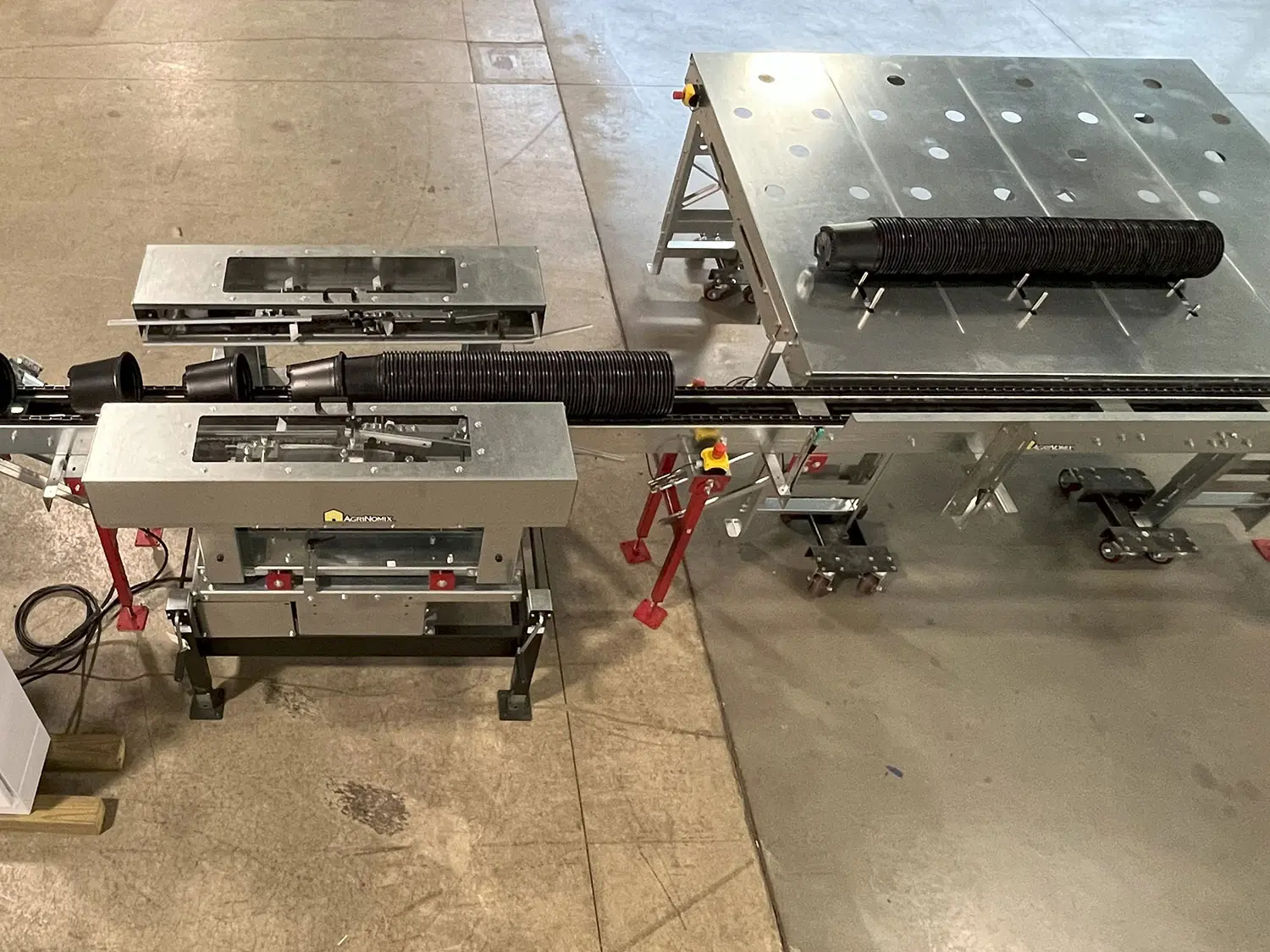

Convertible Cuttings Line

The Convertible Cuttings Line is an affordable in-line sticking and planting system for growers of all sizes. Automates tray feeding to create organized workstations, enabling workers to focus on tasks—case studies show up to 2x increase in output. Upper belt removes when not needed, converting to single-layer operation for various container types. Streamlined design minimizes downtime and maximizes productivity. Reduces manual handling and optimizes workflow to manage labor costs effectively.

Explore Product

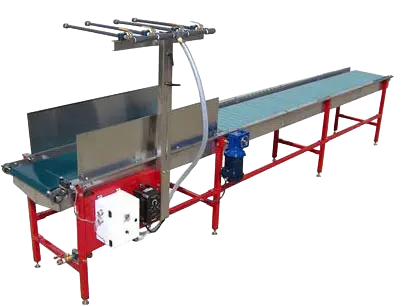

14 Foot Water Tunnel System

The 14 Foot Water Tunnel provides controlled watering for flats, trays, pots, and baskets—with extended dwell time for heavier irrigation needs. Available in 16″ and 22″ widths as either 14-foot powered conveyor or 7-foot powered plus 7-foot gravity roller. Standard variable speed up to 80 ft/min, 4-bar manifold, and drain pans. Wires into line controls—watering stops/starts with production to prevent over/under-watering. Accommodates containers up to 31.5″ tall including hanging baskets.

Explore Product

Pot & Tray Production Line

See System Details

Single Stack Tray Dispenser

Automatically dispenses most common propagation and plug trays. Use stand-alone or integrate into any production line. Load up to 18" tall stacks into the magazine—trays are automatically separated and dispensed via integrated conveyor.

User-adjustable magazine and separation mechanism accommodate different tray sizes. Available in single-stack (manually loaded) or multi-stack (auto-loads via upper conveyor, returns trays via lower belt). All units adjustable to fit many tray types

PD-X1 Pot Dispenser

Automate pot dispensing with the PD-X1, a high-speed system that separates, grips, and places pots into carrier trays with precision. Servo-controlled gantry and vacuum gripper assembly ensure accurate, consistent placement at up to 400 trays per hour.

Swappable cartridges and interchangeable gripper assemblies allow quick changeovers between pot sizes, shapes, and tray configurations. Handles round, stadium, and square pots from 3" to 6.5" diameter.

KVXM Tray and Pot Filler

The KV-XM features a 31.5″-wide heavy-duty double galvanized elevator chain delivering up to .5 yards of soil per minute. Fill trays and pots up to 17.75″ tall quickly and uniformly. Soil density and compaction are precisely controlled by a 4-blade longitudinal rotor, powered roller, leveling auger, and finishing brush, all quickly adjusted with crank handles for fast changeovers. Powered outfeed rollers and conveyor belt efficiently return excess soil to circulation, reducing waste.

Explore Product

High-Speed Dibbler

Dibble holes in pots and flats for uniform placement and planting depth at speeds up to 2,800 containers/hour. High-speed pneumatics and precision controls deliver consistent results. Magnetic dibble pins attach quickly to metallic mounting plate for ultimate flexibility and fast changeovers. Set hole locations by positioning pins directly in the pot or tray, then lower the plate with the built-in hand crank. Versatile design meets the demands of high-speed lines with frequent product changes.

Explore Product

Stand-Alone Conveyors

AdeptAg is the USA partner with Martin Stolze conveyors. Martin Stolze offers an extensive product line of conveyors and attachments, along with many years of experience in horticultural automation. AdeptAg stocks the most popular sizes in Oberlin, OH year-round.

AdeptAg also offers a full line of Stainless-Steel conveyors. These heavy-duty conveyors are constructed to withstand rigorous environments. Stainless steel conveyors can be ordered in lengths of 1-meter increments.

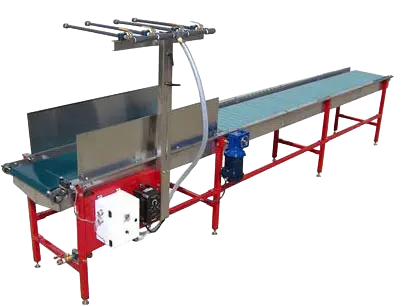

14 Foot Water Tunnel System

The 14 Foot Water Tunnel provides controlled watering for flats, trays, pots, and baskets—with extended dwell time for heavier irrigation needs. Available in 16″ and 22″ widths as either 14-foot powered conveyor or 7-foot powered plus 7-foot gravity roller. Standard variable speed up to 80 ft/min, 4-bar manifold, and drain pans. Wires into line controls—watering stops/starts with production to prevent over/under-watering. Accommodates containers up to 31.5″ tall including hanging baskets.

Explore Product

Pot & Tray Production Line with Transplanter

See System Details

Production Line Conveyors

Production Line Conveyors are proven to significantly reduce material handling and increase productivity. They may be utilized to set the pace of a crew by bringing the work to the workers, verse moving your crew. These conveyors can be integrated into production lines to seamlessly move the product through the various tasks of production from the infeed to the take-off area. AdeptAg has a broad offering of conveyor lengths and widths to fit the various needs for the greenhouse industry.

Explore Product

KV-XL Filler

The KV-XL sets the standard for versatility and reliability. The soil hopper sits directly over the filling belt for even side-to-side filling while minimizing floor space.

Direct drive gearboxes, inverter duty motors, sealed bearings, and heavy-duty galvanized and powder-coated steel construction provide years of low-maintenance operation. Superior soil return uses powered rollers, three belt conveyors, and a short auger. Fills containers up to 22″ wide and 17.5″ high.

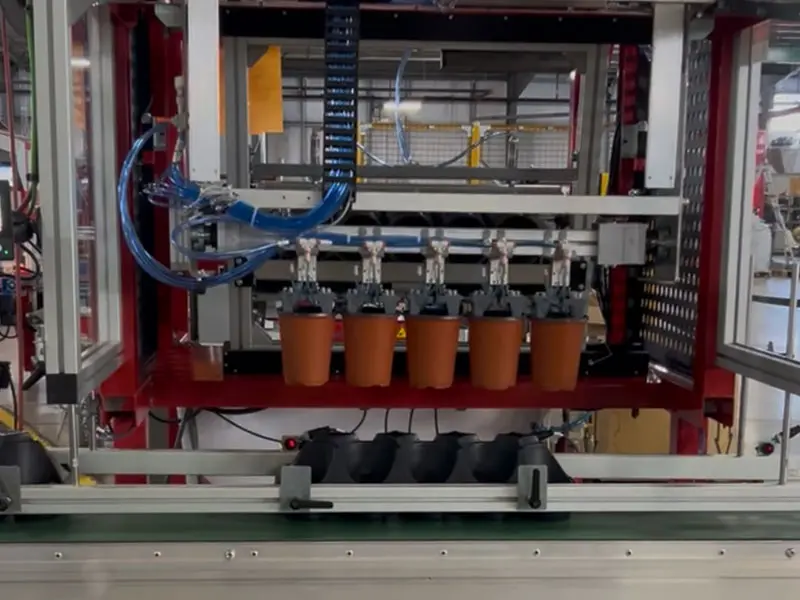

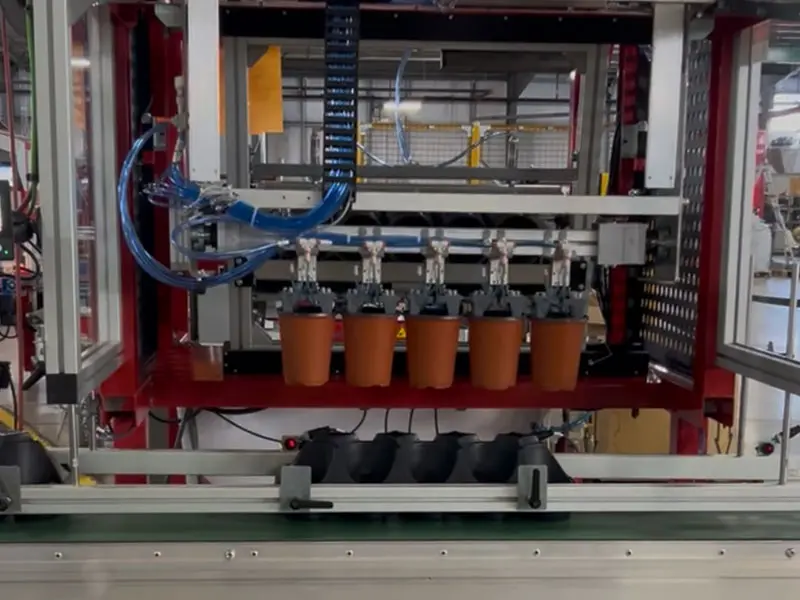

RW1500 Transplanter

The RW1500 Transplanter features advanced electronics and wireless technology for maximum flexibility and efficiency. Up to 24 independent fingers with 1500mm spread transplant up to 24,000 plugs per hour.

Pinching spade gripper design requires no push-up pins, ensuring accurate plant placement and healthy growth. Quick changeovers, plug tray and finish container swaps in minutes. User-friendly touchscreen with electronic depth and height adjustments. Reduces labor costs and boosts throughput.

Stand-Alone Conveyors

AdeptAg is the USA partner with Martin Stolze conveyors. Martin Stolze offers an extensive product line of conveyors and attachments, along with many years of experience in horticultural automation. AdeptAg stocks the most popular sizes in Oberlin, OH year-round.

AdeptAg also offers a full line of Stainless-Steel conveyors. These heavy-duty conveyors are constructed to withstand rigorous environments. Stainless steel conveyors can be ordered in lengths of 1-meter increments.

14 Foot Water Tunnel System

The 14 Foot Water Tunnel provides controlled watering for flats, trays, pots, and baskets—with extended dwell time for heavier irrigation needs. Available in 16″ and 22″ widths as either 14-foot powered conveyor or 7-foot powered plus 7-foot gravity roller. Standard variable speed up to 80 ft/min, 4-bar manifold, and drain pans. Wires into line controls—watering stops/starts with production to prevent over/under-watering. Accommodates containers up to 31.5″ tall including hanging baskets.

Explore Product

Carousel Potting Line

See System Details

PotJet Pot Dispenser

Streamline your potting line with the PotJet Pot Dispenser. Dual opposing spools with custom grooves precisely separate and dispense pots one by one onto your potting machine. Touchscreen control panel lets operators switch between pot sizes quickly with the touch of a button, minimizing downtime and simplifying operation for all skill levels. Designed to reduce manual labor and increase throughput while ensuring consistent, damage-free pot handling.

Explore Product

TM-2432 Potting Machine

The TM-2432 Potting Machine features an ergonomic 14-position carousel turntable with lower working height. Available in single drill (E Model, up to 3,000 pots/hr) or double drill (D Model, up to 5,550 pots/hr).

Handles round pots 3.5"–12.5" and square pots 3"–8.5". Drill creates perfectly centered planting holes. Remote-controlled turntable and elevator with frequency control. Compatible with popular automation and transplanting systems. Adjustable conveyor positioning and 3 emergency stops.

WT-8000 Irrigation Tunnel

Automate watering for both round and square pots as they move along a conveyor belt. Integrated photoelectric sensors precisely detect each pot, allowing adjustable nozzles to deliver the exact amount of water needed. Touchscreen control provides individual water adjustment for precise irrigation—ensuring optimal water for each plant while minimizing waste. Stainless steel contact surfaces and removable side panels simplify cleaning. Easily integrates into potting machine production lines.

Explore Product

PT-5000 Wide Belt

Maximize your pot and tray handling with this customizable buffer table system. Available in lengths from 16' to 39' and 6.5' width. High-quality aluminum profile base, durable multi-layer belt, coated drive and deflection rollers, and weather-resistant galvanized substructure. Push-over unit with straight bar or custom template—optional pneumatic cylinders for triangle pot positioning. Double-bearing push-over ensures stability with heavy pots.

Explore Product

Inline Double Nursery Potting Line

See System Details

CD-X1 Nursery Pot Dispenser

The all-new CD-X1 Nursery Pot Dispenser is a fast, reliable solution for loading nursery pots onto a production line. This pot dispenser works with pots ranging in diameter from 6.5 inches to 15 inches. Pots are mechanically separated quickly and reliably, and then moved along a chain conveyor and tipped upright onto an inline conveyor ready to be filled. The CD-X1 Nursery Pot Dispenser features simple mechanical adjustments that make changeovers for different-sized pots fast and easy.

The Nursery Potter

The Nursery Potter eliminates never-ending potting machine maintenance, no chains or sprockets. This all-belt-conveyor potter delivers unmatched reliability year after year. Heavy-duty motors and gearboxes provide power and torque for virtually any soil mix. The two-cubic-yard galvanized steel hopper ensures longer life and less maintenance. All-belt operation guarantees production won't be hindered by difficult soil that rapidly deteriorates chains and augers.

Explore Product

TP-2400 Pot Topper

Complete the transplant cycle by automatically and uniformly covering plant collars with soil, bark, miscanthus, rice husk, or similar materials. Up to 5,000 pots per hour. Advanced PLC control allows precise settings for each process, minimizing changeover time between pot sizes. Height-adjustable tube leveler skims excess material and recirculates it—no waste. Pot width adjusts quickly with a single lever. Configurable for right or left side loading. Remote touchscreen control panel.

Explore Product

Container Buffer System

The Container Buffer System optimizes forklift movement of plant material by accumulating containers on a buffer belt, ensuring continuous production. Handles up to 4,000 containers per hour—pots from from flats & trays to 15gal pots. PLC control with data collection enables programmable speed and spacing. Wireless remote controlled pause/stop function and side or end pick-off by forklift. Custom buffer sizes available to match your requirements.

Explore Product

See How Growers Thrive with AdeptAg

24/7 Technical Service & Support

Our team of experienced service staff is available 24/7 to support and troubleshoot any issue with your automation systems.

For technical assistance or project support, please contact us.

Custom Solutions for your Operations

Connect with our experts to explore horticulture solutions that drive efficiency and sustainability.