Automation

GROW-n-GO Racks Transportation & Growing System

GROW-n-GO Racks Transportation & Growing System

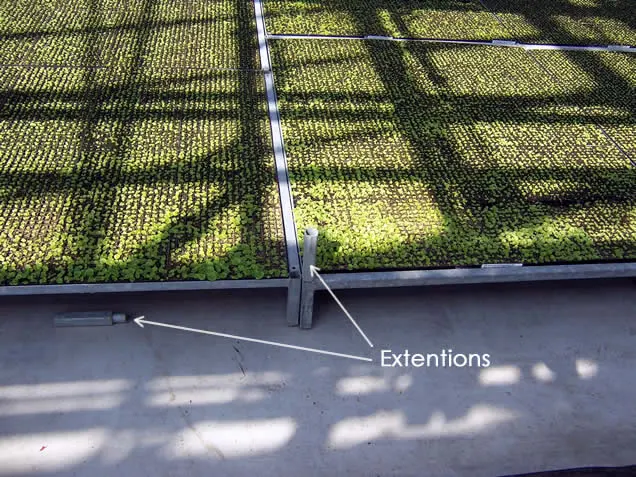

The Grow-n-Go Racks utilize a carts system to move products into the greenhouse, then, the carts’ shelves are easily “un-stacked” and set on the floor for growing. The plants are off the floor, with the beneficial micro-climate forming underneath the racks. From there, the racks can be easily moved to different parts of the greenhouse, accessed for different operations, such as trimming, and then, easily re-assembled for moving, and ultimately, shipping.

For pricing and additional information, contact the AdeptAg Sales team.

Details

Related Products

Custom Solutions for your Operations

Connect with our experts to explore horticulture solutions that drive efficiency and sustainability.