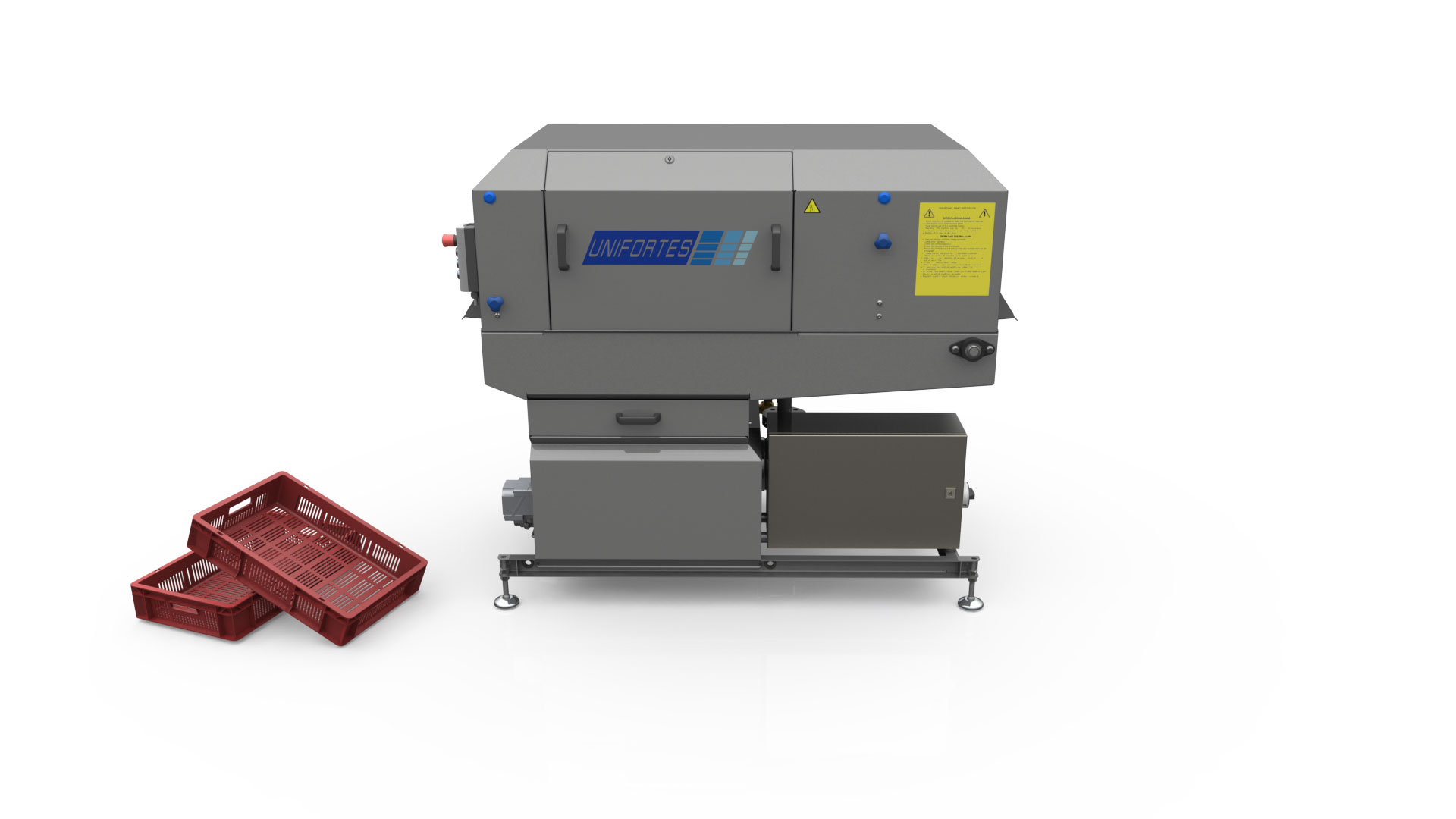

Basic Tunnel Washing Machine

Basic Tunnel Washing Machine

The Unifortes Basic Tunnel Washing Machine is part of the “Basic” series and is specially designed to offer some of the key features of the “industrial” series at a lower capacity and for smaller budgets. The Basic Tunnel Washing Machine is suitable for washing and rinsing crates, trays, and boxes in a wide range of sectors. It consists of a washing section and a rinsing section. Due to its smart design, it will be available in a wide range of varieties. Through its compact design, the Basic Tunnel Washing Machine is suitable for washing capacities of up to 100 products/h. The Basic Tunnel Washing Machine is customized according to the specific product that needs to be washed, based on standard A-brand components. This guarantees a versatile machine with the optimal cleaning result.

Unifortes Basic Tunnel Washing Machine

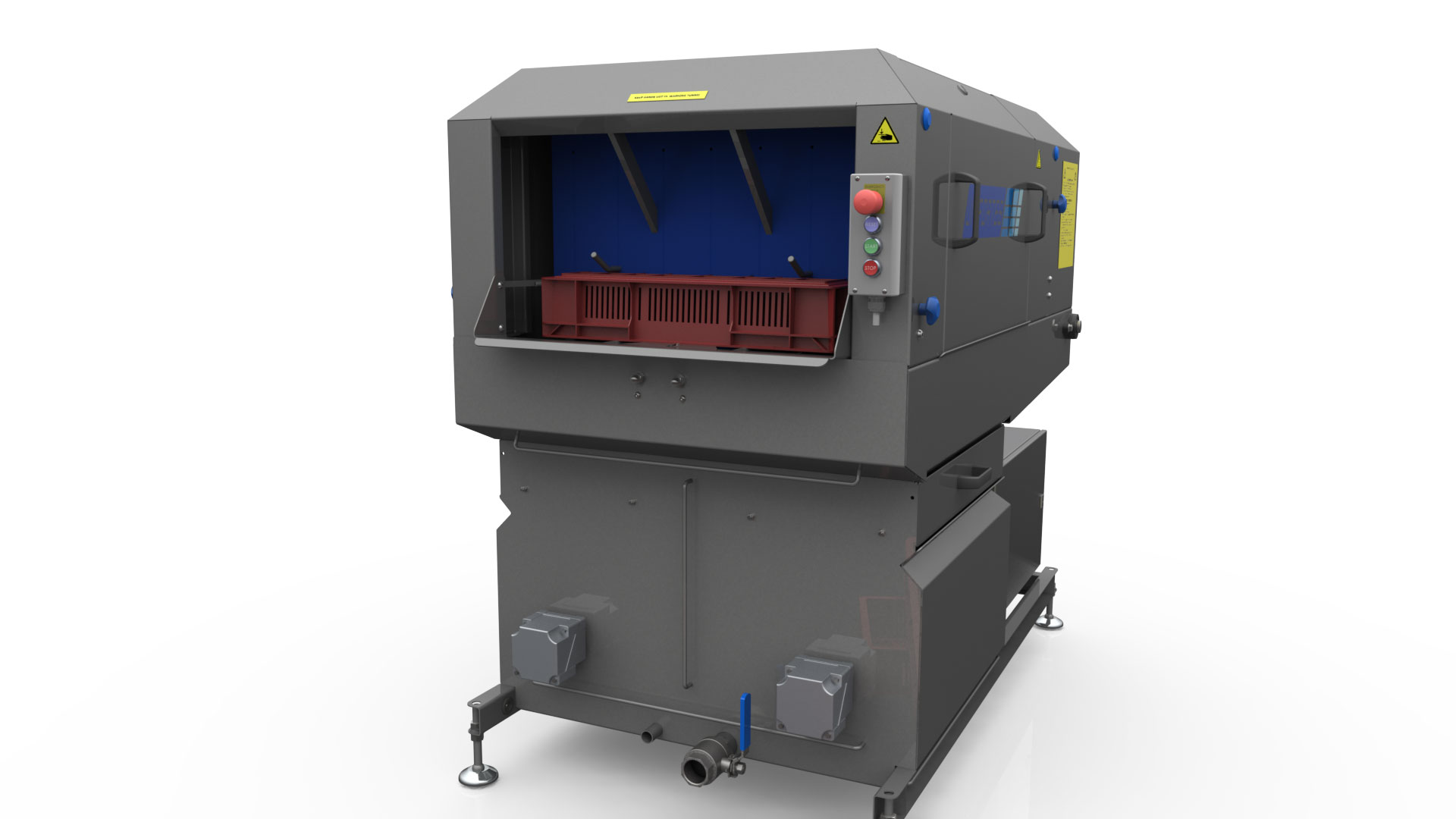

Hygienic construction

The Basic Tunnel Washing Machine is fully constructed out of corrosion-resistant stainless steel. It features an open design with hatches on both sides that you can remove for thorough cleaning. When the machine is off, the hatch can be opened and the filter can be removed for cleaning the whole machine.

Economic

To reduce operating costs the machine applies numerous features to minimize water- and power consumption. The washing water is collected, filtered, and reused to minimize the usage of water, chemicals, and heating energy.

Safety precautions

Machine safety is a very important concern for Unifortes. All Unifortes machines are built according to the CE guidelines. All critical elements are shielded by the proper safety measures. The machine has an emergency stop and a lock on the main hatches.

Options

There is a range of options available to extend the functionality of the machine. These options include heat exchangers or steam heating systems for the tank. Other possible options are for instance extended in- and outfeed tables. The AdeptAg team is happy to advise you on how to get the best machine for your application. The available options are:

- Extended in,- and out-feed tables (non-driven)

- Adjustable transport speed

- One man operation

- Hot water heat exchanger or steam injection

- Chemical dosing unit on the rinsing

Basic Tunnel Washing Machine Technical specifications

All specifications are based on E2 crates, specifications can deviate with a different type of crate

General data |

|

| Capacity | Up to 100 crates/h |

| Width variation | 300 mm to 600 mm |

| Height variation | 50 mm to 240 mm |

| Transport height | 900 mm |

| Material | AISI 304 |

Electrical data |

|

| Voltage | 400V 3ph + 0 + N 60Hz |

| Total power consumption | 16 kW (3ph 32A connection with 1x12kW element) |

Technical data |

|

| Pump washing section | 3 kW stainless steel centrifugal pump including Sic-Sic Seal for abrasive pollution

450 liter/min at 2,5 bar |

| Spray system | 3 seamless bended spray lines around transport system with flat pattern spray nozzles |

| Heating system washing section | 12 kW (1x 12kW electrical heating elements) |

| Washing temperature | Adjustable via a thermostat in the control panel |

| Tank volume | 250 liters |

| Main filter | Stainless steel perforated plate, 1.5 mm opening |

| Connection water supply | 2x 0,5” |

| Connection water drainage system | 1x 1,5” |

| Rinse system | Seamless bended spray lines around the transport system with flat pattern spray nozzles |

| Rinse water consumption | 100 litre/h |

Transport system data |

|

| Transport type | Single AISI 316 chain with carriers |

| Transport motor power | 0.18 kW |

| Transport motor type | IP66-certified motor and transmission

Special coating for extra protection against water and chemicals |

| Side guides | Manual adjustable side guides |

| Top guides | Manual adjustable top guides |

Size and weight |

|

| Length | 1.500 mm (excluding in,- and outfeed tables) |

| Width | 900 mm |

| Height | 1.400 mm |

| Weight | 500 kg |

For more information on the Unifortes Basic Tunnel Washing Machine, please contact your AdeptAg sales representative.