Single Layer Benches

Single Layer Benches

Growing on the floor works well for large pot sizes, patio planters, and even flats. However, managing 2″ to 6″ potted crops or 105 propagation trays requires specialized solutions. AdeptAg excels in providing benching solutions tailored to every grower’s needs.

Our benches can be customized to any width up to 8 feet and any length in 6-inch increments. They can be either rolling or stationary. Surface options include trough, flood liners, and expanded metal.

Trough System Benefits and Features

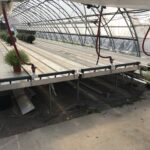

Trough benching has been around since the 1980s and is the perfect ebb and flood system for many potted plant cultivars. These tables are designed with a slope of 4” per 100’, allowing water to flow downhill past the plants, which take up water through capillary action. The troughs are gapped to ensure airflow through the crop. This system can water several thousand square feet in just 8 minutes and is also used for lettuce production.

Benefits

- Consistent growing conditions

- Excellent airflow within crops

- Increased plant density per square foot

- Easy installation

- Fertilizer savings

- Water cost savings

- Suitable for lettuce production

- Labor efficient

- Cost-effective recirculation

- Durable and long-lasting, made from clear-coated white aluminum

- Direct growing in shuttle trays

Features

- Adjustable table heights

- Available in rolling or stationary bench options

- Standard anti-tip bracket

- Optional heat supports

- Common sizes: 7⅜”, 9¾” (measurements indicate growing surface)

- Additional sizes available

EBB & Flood System

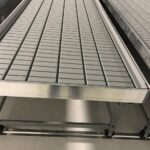

Ebb and flood benching has been in use since the 1950s when benches were made of concrete and were stationary. Modern benches are much more sophisticated, available in various lengths, and offer a cost-effective solution to the evolving market. Whether growing mini 2” potted Kalanchoes or large planter pots, ebb and flood benching is flexible enough to accommodate almost any potted plant for sub-irrigation. FDA-approved PVC polystyrene trays are inserted into our standard bench systems, making this system ideal for saving water and fertilizer while enhancing crop quality.

Benefits

- Lightweight

- Durable, rugged construction

- Automatic, even watering

- Easy assembly

- Easy to clean

Features

- Aluminum or stainless steel construction

- Ebb and Flood or drain-to-waste systems

- 6″ leg height adjustability

- Various size options

- Available in rolling, stationary, or gliding options

- FDA approved

- UV stable

- The first step toward recirculation!

Expanded Metal

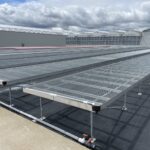

Expanded metal benches from AdeptAg are crafted from galvanized materials and engineered for today’s work environment. These benches are available as stationary benches, rolling benches, or even glider benches (see page 16 for details on this new product). They are most commonly used for propagation spaces, retail applications, or to support drip system-fed potted crops. AdeptAg benches can be constructed directly on ground cover, supported by a post hole, or fastened to a concrete floor.

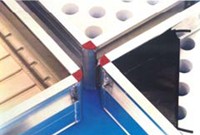

AdeptAg benches feature aluminum side profiles, anti-tip mechanisms, roller stops, and durable HDPE-formed corners that completely cover the rough edges of the expanded metal, providing a finished look. All benches offer 6-8″ of height adjustment in the legs to accommodate uneven floors. The frame structure used in expanded metal benching is the same as that used for flood and trough benching. Every bench is custom-made to suit your layout, with no size limitations.

Expanded metal tops are available in two finishes: raised expanded metal and flattened expanded metal. Raised expanded metal is stronger, while flattened expanded metal is ideal for sliding trays without snagging. Cross supports on raised expanded metal tables are spaced at 24″, while 16″ spacing is required for flattened metal installations to maintain the same level of strength.

Benefits

- Air pruning for root systems

- Good airflow

- Lightweight

- Simple to construct

- Anti-tip construction

- Available in stationary or rolling options

- Galvanized construction

- 6″ adjustable legs

- Optional integrated heat supports

Customization

- Can be built on soil or concrete

- Available in raised or flattened expanded metal

- Sidewalls can be flush with expanded metal or constructed as raised sidewalls

- Sizes customized to grower preference or crop requirements:

- Length: 8′ to 150′

- Width: 2′ to 8′

- Height: 14″ to 36″

Glider Series

The Glider Bench Series is constructed with a reinforced galvanized steel framework and operates on a wheel-and-track system. Centre legs have solid smooth wheels, while end legs feature V-grooved wheels that run on a floor-mounted aluminum inverted V-track. Customizable in lengths from 8ft to 30ft, these benches glide effortlessly side-to-side, creating a 24″ walkway. For specific building code requirements, rooms can be designed with wider walkways, eliminating wasted space.

The Glider Series Benching can be topped with Trough, Ebb and Flood, or Expanded Metal, and can also be configured as a multi-level system to suit various growing needs.

Benefits

- Maximizes growing space

- No gapping between benches is required

- Rigid steel construction

- Easy to clean and maintain

- Strongest bench in the industry

Features

- Available in single, 2, or 3-level glider bench options

- Table lengths up to 30′ (9.14 m)

- Standard table widths of 48″ (122 cm) and 52″ (132 cm) available in multi-level options

- Options for aluminum bench tops with high impact 44″ (112 cm) polystyrene liners or aluminum trough decking

- Single-level height adjustment: +/- 4″

- Multi-level height adjustment: +/- 4″

- Suitable for drip irrigation collection or ebb and flood systems

- Single liner along the entire length (no 8′ sections)

For more information on Single Layer Benches, please contact your AdeptAg sales representative.