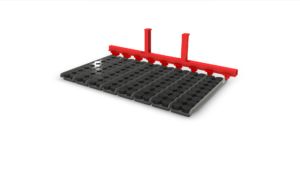

AdeptAg Pot Forks

AdeptAg Pot Forks significantly reduces the labor required to move plants around the greenhouse or nursery. When used in combination with Buffer Belt Systems, Pot Forks can dramatically reduce a grower’s labor requirements for material handling. Hundreds of pots are moved at one time with a set of AgriNomix Pot Forks. Forks can be used to load and unload carts/wagons and set down in the growing area.

Pot Forks are engineered to fit on the Prins Maasdijk Trike, Electro, Boxer, and other traditional forklifts. Forks are custom-designed based on the pots, wagon size, and greenhouse/nursery spacing. The rugged mast will handle lifts over 2000 pounds. Tines are attached to the mast with individual brackets to allow for adjustability. The top side of the fork has laser-cut “Y” shaped serrated edges which help secure pots on the tines. The 2-part pressed form of the tine is designed for strength and to align pots upon entry and pick-up.