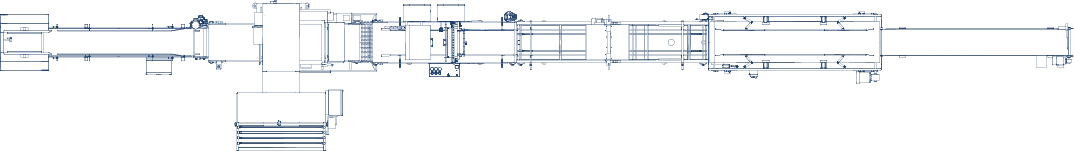

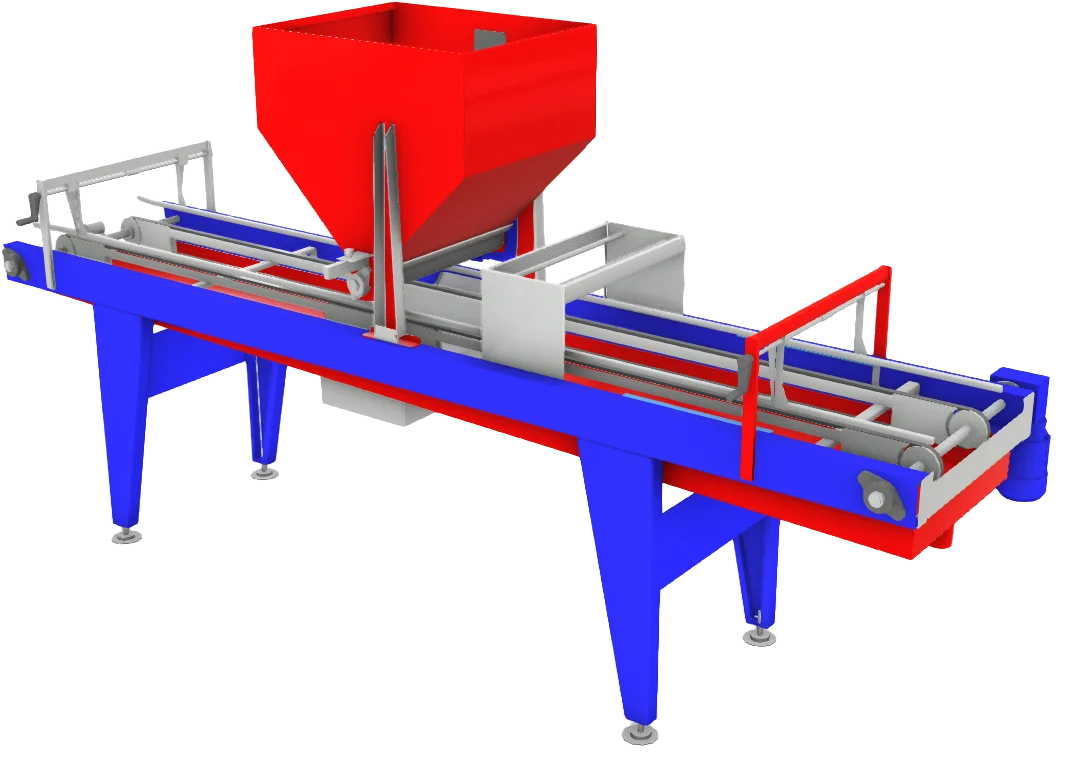

Automatically dispenses shuttle trays, plug trays, and individual packs. Use stand-alone or integrate into any production line. Single-stack model is manually loaded; multi-stack version auto-loads stacks via upper conveyor and returns dispensed trays via lower belt. Adjustable settings accommodate a wide range of tray sizes. Throughput up to 2,100 flats per hour (multi-stack). Reduces labor costs and increases efficiency for operations handling a variety of plants and container sizes.

High Throughput

Up to 2,100 flats per hour (multi-stack version)

Automatic Stack Loading

Upper conveyor loads stacks, lower belt returns dispensed trays (multi-stack)

Flexible Integration

Use stand-alone or integrate into production lines

Adjustable Settings

Accommodates a wide range of tray sizes

Multiple Tray Types

Handles shuttle trays, plug trays, and individual packs

Reduced Labor Costs

Automates tray handling for improved efficiency

Capacity: Pack Dispenser 660/hr, Single Stack 910/hr, Flat Destacker 910/hr, Multi-Stack 2,100/hr

Power: Single & Flat Destacker 110 VAC; Multi-Stack 230 VAC

Air: 8 CFM @ 100 PSI