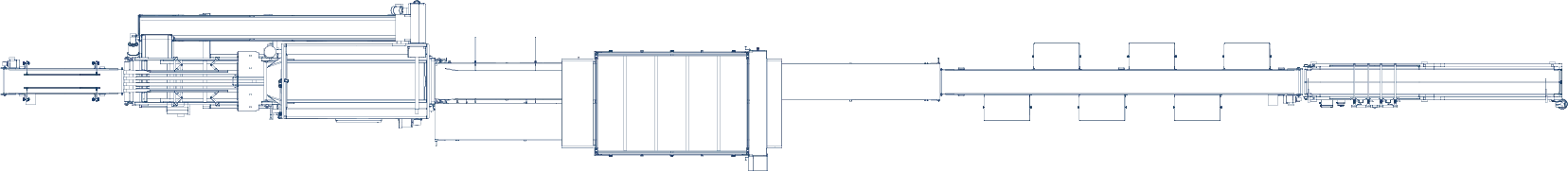

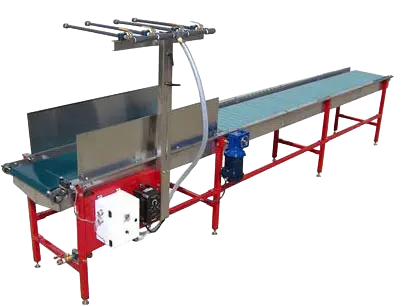

Production Line Conveyors are proven to significantly reduce material handling and increase productivity. They may be utilized to set the pace of a crew by bringing the work to the workers, verse moving your crew. These conveyors can be integrated into production lines to seamlessly move the product through the various tasks of production from the infeed to the take-off area. AdeptAg has a broad offering of conveyor lengths and widths to fit the various needs for the greenhouse industry.

Features (Martin Stolze Aluminum Frame):

- Lightweight

- Roller bed

- Variable Speed Drive

- Integratable (With other AgriNomix equipment)

- Available in Widths of 10”, 16”, & 24” (Custom widths available)

- Available in Lengths of 3’ to 29.5’

Features (AdeptAg Stainless Steel Frame):

- Heavy Duty

- Roller bed

- Variable Speed Drive

- Integratable (With other AgriNomix equipment)

- Available in Widths of 16” & 24” (Custom widths available)

- Available in Lengths of 3’ to 29.5’

- Power: 110/220 VAC, 1P or 3P

- Motor: 1 HP

- Manufacturer: Martin Stolze (aluminum), AdeptAg (stainless steel)

Production Line Conveyors Options:

- 90-degree turns (powered and non-powered)

- Fixed or adjustable leg heights

- Reversing

- Transfer rollers between other equipment

- Push or pull bars

- Caster kits

- Folding work stations

- Accessories: emergency stop, remote control, direction switch, height adjustable supports, incline, adjustable end-of-line switch

Multiple Widths – 10″, 16″, or 24″ (custom widths available)

Multiple Lengths – 3′ to 29.5′