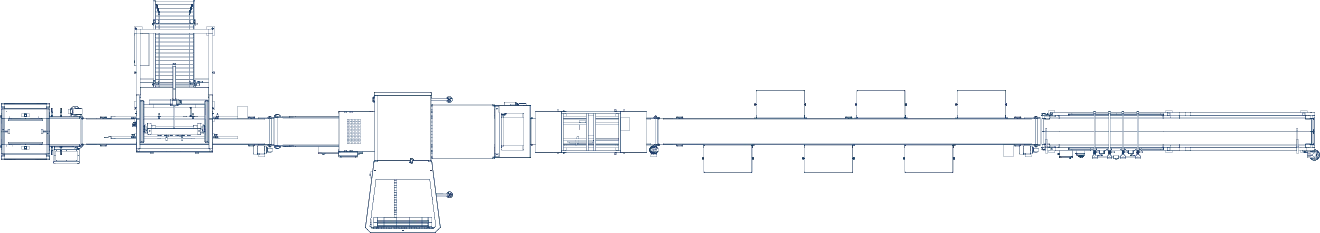

Automatically dispenses most common propagation and plug trays. Use stand-alone or integrate into any production line. Load up to 18" tall stacks into the magazine—trays are automatically separated and dispensed via integrated conveyor.

User-adjustable magazine and separation mechanism accommodate different tray sizes. Available in single-stack (manually loaded) or multi-stack (auto-loads via upper conveyor, returns trays via lower belt). All units adjustable to fit many tray types

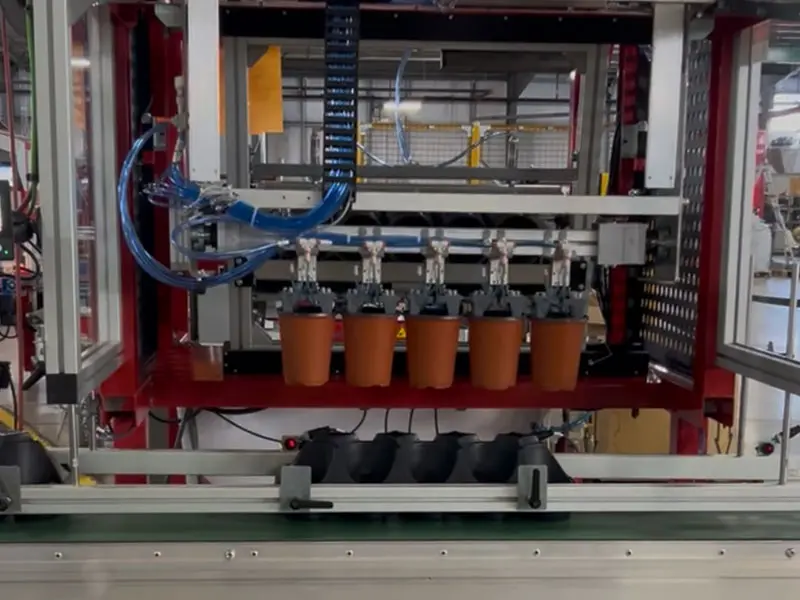

Automatic Separation

Trays are separated and dispensed from integrated conveyor belt

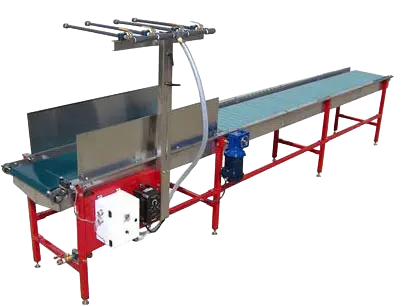

Variable Belt Speed

Adjust output rate to match production line pace

Flexible Integration

Pre-wired for flat fillers or other production equipment

Adjustable De-Nester

User-adjustable magazine and separation mechanism for different tray sizes

Electronic Photo Eye Control

Precise tray detection and dispensing

Two Versions Available

Single-stack (manually loaded) or multi-stack (auto-loads and returns via dual conveyors)

Capacity: Up to 910 trays/hr

Tray Sizes: Up to 24″L × 16″W

Air: 8 CFM @ 100 PSI

Power: 230 VAC 3-phase, 3 A

Dimensions: 52″L × 35″W × 56″H