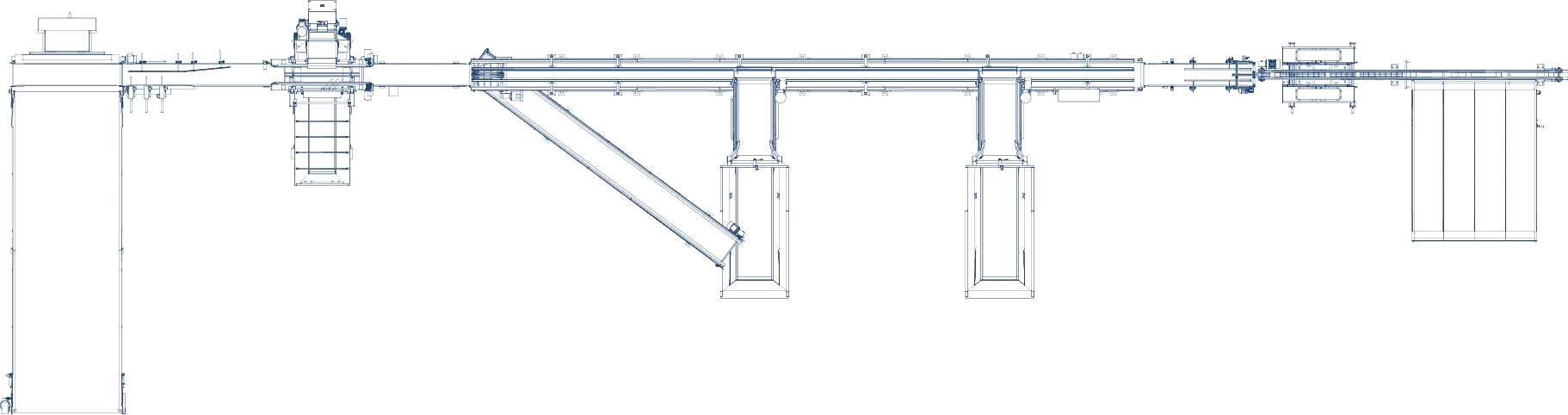

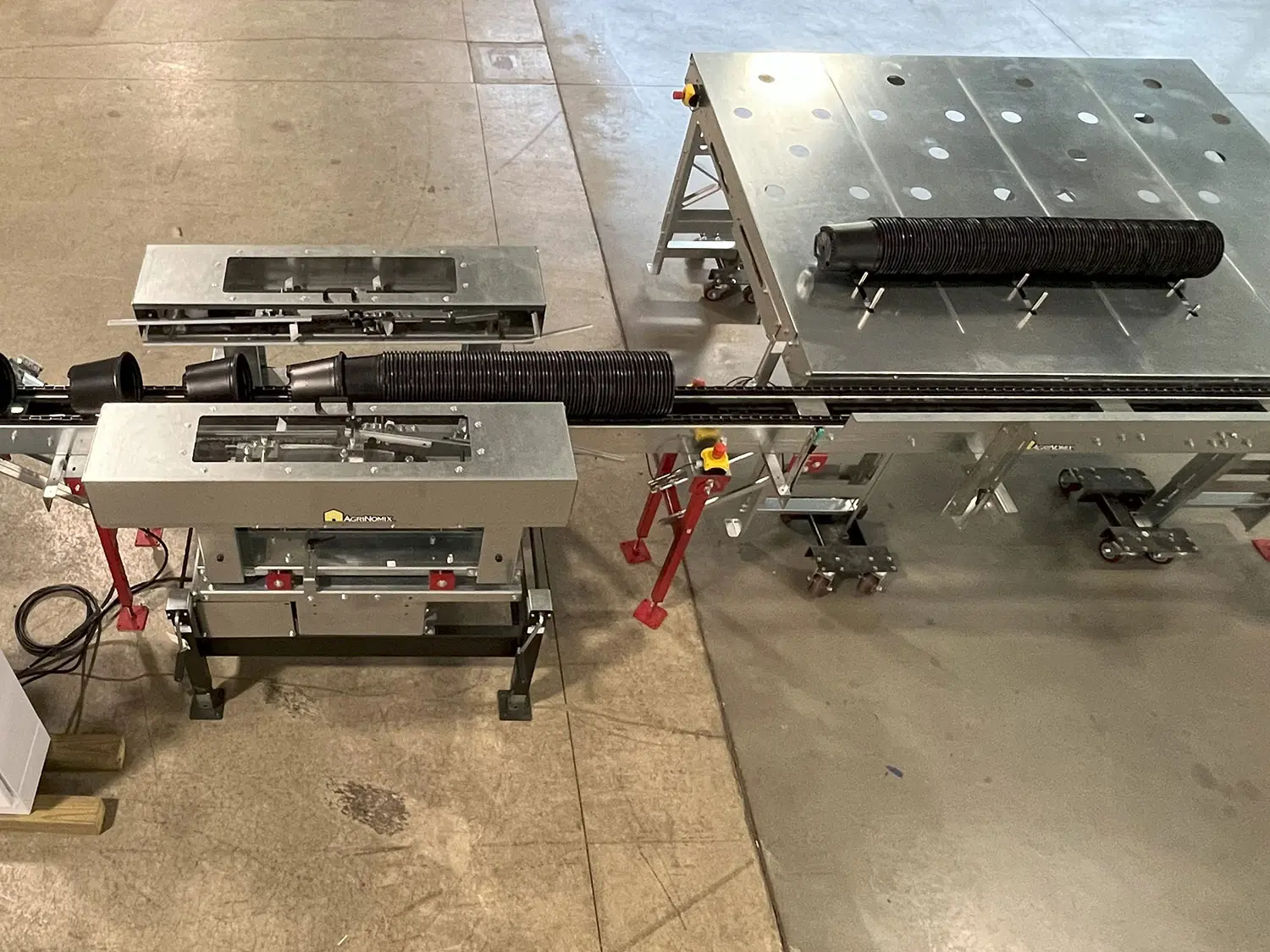

The all-new CD-X1 Nursery Pot Dispenser is a fast, reliable solution for loading nursery pots onto a production line. This pot dispenser works with pots ranging in diameter from 6.5 inches to 15 inches. Pots are mechanically separated quickly and reliably, and then moved along a chain conveyor and tipped upright onto an inline conveyor ready to be filled. The CD-X1 Nursery Pot Dispenser features simple mechanical adjustments that make changeovers for different-sized pots fast and easy.

Wide Container Compatibility

Handles 6.5" to 15" diameter pots (1-gallon to 15-gallon nursery containers).

Reliable Pot Separation

Mechanically separates individual pots from horizontal stacks quickly and consistently.

Pots Delivered Upright and Ready

Chain conveyor tips pots upright onto inline conveyor, ready for filling without manual handling.

High-Volume Throughput

Up to 1,000 pots per hour keeps pace with large-scale nursery operations.

At-a-Glance Monitoring

10" color touchscreen HMI displays pots dispensed, runtime, and operational status.

Fast Size Changeovers

Simple mechanical adjustments between pot sizes without complex tooling or downtime.

Precise Operation Control

PLC and variable frequency drives ensure consistent, reliable dispensing.

North American Safety Certified

UL508a and CSA C22.2 No 14 compliant.

- Pot range: 6.5″–15″ diameter (1–15 gallon)

- Throughput: Up to 1,000 pots/hour

- Dimensions: 28’6″ L × 8’10” W × 3’10” H

- Storage table: 6’2″ × 7’6″ galvanized steel

- Control: PLC with variable speed chain conveyors and VFD

- Interface: 10″ color touchscreen HMI

- Power: 120 VAC or 230 VAC

- Air: 80 PSI / 4 CFM