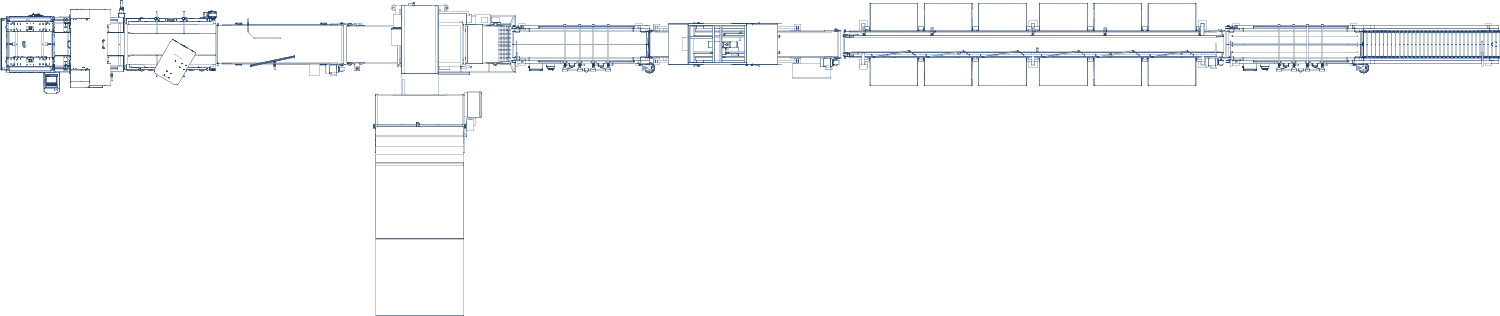

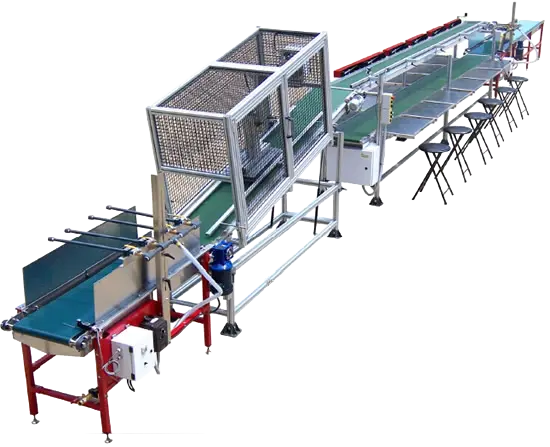

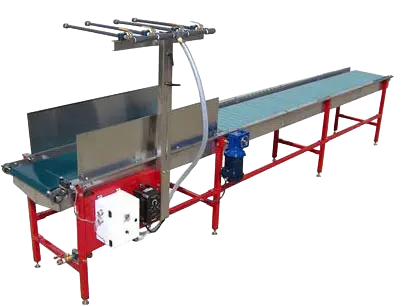

Streamline your propagation process by automating the precise placement of Growcoons into trays. The Advanced model uses pick and place technology to deliver up to 56,000 Growcoons per hour at 1.2 seconds per row with superior accuracy and reliability.

Handles heights from 0.7–2.8" and top diameters from 0.4–3.9" across a wide range of tray and Growcoon combinations. Integrates into existing tray filling lines with optional tray destacker for continuous operation

- Pick and place system for superior accuracy over traditional drop method

- Up to 56,000 Growcoons per hour capacity

- 1.2 second fill time per row

- Compatible with multiple Growcoon/tray combinations

- Tray dimensions: 9.8–23.6″ (short edge/long edge)

- Integrates into existing tray filling lines

- Energy-efficient and low-maintenance operation

- Designed to scale with production needs

Capacity: Up to 56,000 Growcoons/hr*

Fill Time Per Row: 1.2 sec

Growcoon Height Range: 0.7–2.8″

Growcoon Top Diameter: 0.4–3.9″

Tray Dimensions: 9.8–23.6″ (SE/LE)

Output Method: Pick & Place

Dimensions: 12’10″L x 4’7″W x 5’3″H

Power (USA/CA): 208V, 3-Phase

Compressed Air: 7.5 bar

*Capacity based on specific circumstances. Contact us for application-specific output estimates.

Options

Tray destacker for improved workflow

Custom tray/Growcoon configuration support