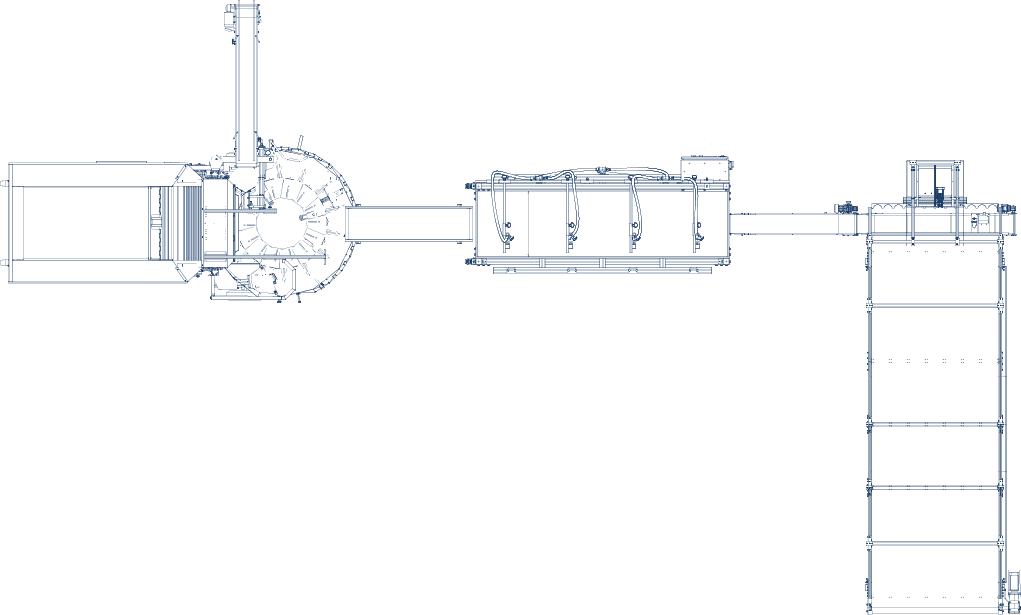

Carousel Potting Line

The TM-2432 Potting Machine features an ergonomic 14-position carousel turntable with lower working height. Available in single drill (E Model, up to 3,000 pots/hr) or double drill (D Model, up to 5,550 pots/hr).

Handles round pots 3.5"–12.5" and square pots 3"–8.5". Drill creates perfectly centered planting holes. Remote-controlled turntable and elevator with frequency control. Compatible with popular automation and transplanting systems. Adjustable conveyor positioning and 3 emergency stops.

High Throughput

E Model up to 3,000 pots/hr; D Model up to 5,550 pots/hr

14-Position Carousel

Ergonomic turntable with lower working height; smooth, quiet operation at high speeds

Centered Planting Holes

Drill creates perfectly centered holes for consistent plant quality

Wide Pot Compatibility

Round pots 3.5"–12.5", square pots 3"–8.5"

Remote Control

Turntable and elevator remotely controlled; frequency control for drill motor, elevator, and soil volume

Safety Features

Ergonomic design with 3 emergency OFF switches

E Model (Single Drill):

Round Pots: 4.5″–12.5″ (11.4–31.8 cm)

Square Pots: 3″–8.5″ (7.6–21.5 cm)

Throughput: Up to 3,000 pots/hr

D Model (Double Drill):

Round Pots: 3.5″–12.5″ (8.9–31.8 cm)

Square Pots: 3″–8.5″ (7.6–21.5 cm)

Throughput: Up to 5,550 pots/hr

Automate watering for both round and square pots as they move along a conveyor belt. Integrated photoelectric sensors precisely detect each pot, allowing adjustable nozzles to deliver the exact amount of water needed. Touchscreen control provides individual water adjustment for precise irrigation—ensuring optimal water for each plant while minimizing waste. Stainless steel contact surfaces and removable side panels simplify cleaning. Easily integrates into potting machine production lines.

Precise Pot Detection – 4 nozzles with light barriers detect each pot for accurate watering

Minimizes Water Waste – Precise delivery plus almost 100% recycling of excess water

Adjustable Water Pressure – 3–8 bar (44–116 psi) for precise delivery

Touchscreen Control – Individual water adjustment for precise irrigation

Round and Square Pots – Waters pots from 3½” to 16″ diameter

Stainless Steel Contact Surfaces – Durable and easy to clean

Removable Side Panels – Simplifies cleaning and maintenance

Flexible Installation – Stand-alone or combinable with other machines

Mobile Chassis – Lockable swivel castors for repositioning

Pot Sizes: 3½”–16″ diameter

Nozzles: 4 nozzles with light barriers

Water Pressure: 3–8 bar (44–116 psi)

Conveyor Belt Width: Up to 16″ (custom lengths available)

Operating Height: 37″

Contact Surfaces: Stainless steel

Chassis: Lockable swivel castors

Dimensions: 6’7″L × 3’W × 6’3″H

Weight: 463 lbs

Power: 230V / 50 Hz

Noise Level: 75 dB(A)

Maximize your pot and tray handling with this customizable buffer table system. Available in lengths from 16' to 39' and 6.5' width. High-quality aluminum profile base, durable multi-layer belt, coated drive and deflection rollers, and weather-resistant galvanized substructure. Push-over unit with straight bar or custom template—optional pneumatic cylinders for triangle pot positioning. Double-bearing push-over ensures stability with heavy pots.

Customizable Buffer Table

Available 16' to 39' length, 6.5' width (custom sizes available)

Durable Construction

Aluminum profile base, multi-layer belt, galvanized substructure

Push-Over Unit Options

Straight bar or custom template, up to 16" width

Triangle Formation

Optional pneumatic cylinders for pot positioning

Double-Bearing Push-Over

Maximum stability with heavy pots

Industry 4.0 Touchscreen

Easy programming of additional pot sizes

Data Mirroring

Performance data accessible on smartphone or tablet

Forklift Ready

Starting aids for forklift trucks

Pre-Collection Belt Options

Clocked collector belt, pneumatic stop cylinders, or mechanical clicker

Length: 16’–39′

Width: 6.5′

Push-Over Width: Up to 16″

Custom Solutions for your Operations

Connect with our experts to explore horticulture solutions that drive efficiency and sustainability.